J Series – Large Glass

Cugher Glass Silk Screen Printing Solutions

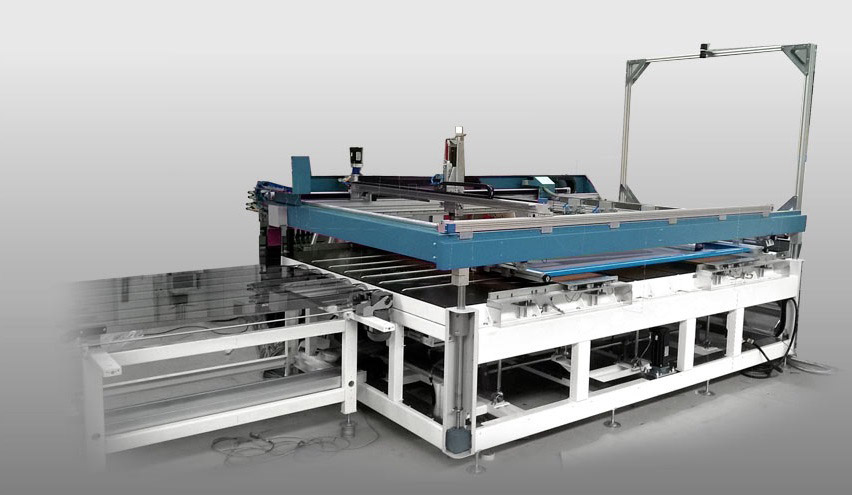

The Series J fully automatic Silk Screen Printing Machine is composed of an entry/pre- alignment conveyor, the printing machine body and an exit synchronized conveyor. The machine has a firm structure with the printing table made by a specially treated aluminium and it is equipped with a belt transport system and an auto-centering. The J Series is built with high quality and efficiency materials, thus the maintenance operations are extremely reduced and simplified.

Main Features

- Height of working table: 950/± 25 mm.

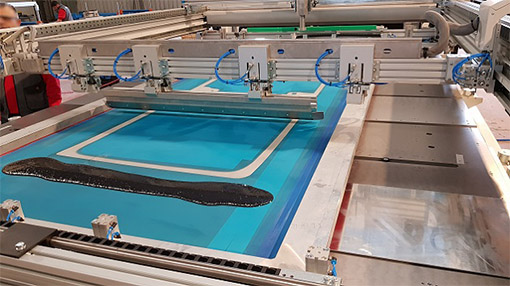

- Squeegee and flood bar group:

— transport system mounted on tempered guides.

— pressure adjustment via proportional valves.

— independent speed adjustment.

— quick locking

— rotation

— use of both Vulkollan squeegee sides before new sharpening.

— flood bar made of AISI 304, with side wings

- Extractable screen. No need of position re-registering.

- Automatic screen height adjustment ensuring perfect parallelism

- Automatic adjustment of the Peel off.

- Auto-learning of the printing stroke length.

- Number of stored recipes adjustable to the customer needs*

Printing machine |

Glass thickness |

Glass min. size (rectangle) |

Glass max.size(rectangle) |

Max. cycle time(av.glass size) |

|

|---|---|---|---|---|---|

| mm | mm | mm | pcs/h | s | |

| Series J 70x100L | 1,4 – 20 | 150×200 | 700×1000 | 474 | 7,6 |

| Series J 130x200S | 1,6 – 20 | 300×400 | 1300×2000 | 297 | 12,1 |

| Series J 160x250S | 1,6 – 20 | 400×800 | 1600×2500 | 266 | 13,5 |

| Series J 160x310S | 2,0 – 20 | 400×900 | 1600×3100 | 235 | 15,3 |

| Series J 160x350S | 2,0 – 20 | 400×1000 | 1600×3500 | 219 | 16,4 |

| Series J 200x300S | 2,0 – 20 | 500×800 | 2000×3000 | 240 | 15,0 |

Contact us today for more custom options: 336-549-6003