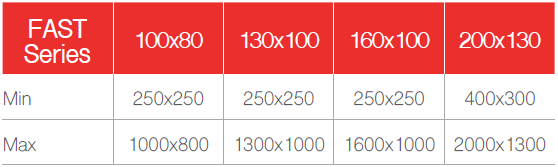

Fast Series Printing Machine

The main features of the Fast series are:

- Possibility to set different speeds for squeegee bar and scraper

- Anti-drip system, on the printing bridge (squeegee bar / scraper group)

- Constant pressure of squeegee bar and scraper, which can be set from the recipe on the operator panel

- Quick and easy frame registration, with micrometric precision on all directions, including rotation

- Adjustable height of printing head, depending on glass thickness and to make cleaning and maintenance operations easier

- Frame extraction without losing the registers and pneumatic locking of the same.

- Possibility to raise the printing head up to 500 mm to facilitate cleaning / maintenance operations (in total 1500 mm from the floor.

- Anodized and ground aluminum printing table, provided with belts for moving the glass in order to be able to handle even holed glass.

- Cycle time: 6 seconds: with maximum glass size – 800 x 1000 mm – possibility to print up to 600 glasses / h

- Recipes based printing machines and lines for quick setup & changeover.

FAST SERIES IS LIKE A DIGITAL CALIBER

Our system allows a perfect control of the height of the printing bridge, having a height position precision higher than 0,1 mm.

The vertical movements of the printing bridge are controlled as a digital caliber, which has the “zero” represented by the printing table (perfectly flat, even surface) and the operator can set the desired height into the touch panel.

PLUS

The front pins for the quick centering change on printing table switch from two to four and are automatically selectable from the recipe, based on the glass size.

Through the selection of the recipe, the operator engages the internal or external pair according to the dimensions of the glass being processed.This allows an even more precise centering.

The replacement of the pins, in case of wear, occurs in a few seconds.

The new side bars on the pre-centering have been modified so that there are no screws in contact with the glass even when the bars start to wear out.

The replacement of the nesting plates is done simply and quickly through dedicated knobs on the top.

Motorized Peel Off adjustable from the operator panel: this functionality has been automated and now the setting of the peel off is done directly from the recipe.

New nesting plates system on the printing table: the new nesting plates were built and mounted on the printing table to optimize the centering of the glass.

The new belts for glass movement are stronger and quick to replace.

EASY CLEANING WITHOUT LOSING SCREEN REGISTER

Pull out of screen with pneumatic Screen Frame Locking System.

The screen can be locked in position by means of pneumatic cylinders and it’s possible to use frames of different heights.

Thanks to this feature, the operator doesn’t need to lock manually the frame, and the insertion and extraction of the screen results to be an extremely fast and easy operation.

Contact us today for more custom options: 336-549-6003