Vision Series: Glass Inspection

INCREASED QUALITY CONTROL AND PRODUCTION MONITORING FOR INDUSTRY 4.0

Automation and constant production monitoring are the main features of Industry 4.0, and, when applied to production cycles, artificial vision systems allow to monitor and automatically set some production parameters.

Cugher Glass offers the opportunity to control the glass in the best way possible and print quality in each and every detail – thanks to the very high resolution reached by its devices – as well as to monitor and adjust the process using optical systems designed for automatic screen centring and automatic control of broken screens. The high potential of customization and constant objectivity in evaluation make artificial vision systems the right solution to achieve 100% automated production control.

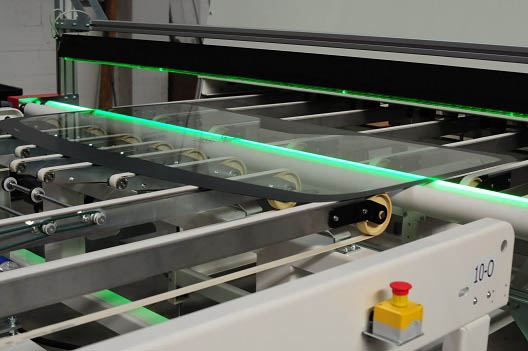

AUTOMATIC GLASS QUALITY INSPECTION VISION SYSTEM

The system, typically installed downstream the washing machine, is able to scan the whole glass and detect any defect present on the raw glass such as scratches, breakages, air bubbles, chips, contaminations, water drops, wet edges.

The system inspects raw glass or cut and grinded glass trough a specifically designed optics technology that uses an alternate light source pattern which can detect any type of glass defect, even lighter ones.

During the setup phase, the quality manager defines the desired level of sensibility for every type of defect. Moreover, different sensibility areas can be defined on all the glass surface to set a higher sensitivity in the center instead of close to edges.

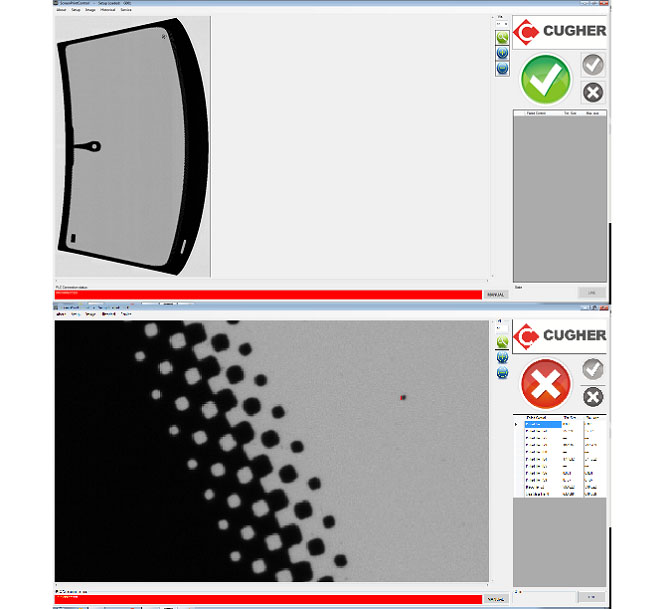

AUTOMATIC PRINT QUALITY VISION SYSTEM

The system, installed immediately after the printing machine, recognizes the any “slavering” or “widening” of the design’s details due to an excess of ink coming from the screen. The inspection is able to detect fade out dots, pin hole, or if there are missing parts of the design and alerts the operator to verify the possible cause.

All the areas of the glasses will be checked and compared with the allowed tolerances specified in the glass inspection recipe, which is created “una tantum” Different sensibility areas can be defined on all the glass surface to allow a higher control, for instance on Logo and Barcodes.

The advantages of this innovative system are the possibility to verify the print quality tracking the defects on imagines and to correct in automatic, in case of errors, the frame position without stopping the conveyor.

The hardware on these two technologies foresees the use of a high resolution monochromatic linear camera with 16384 pixels, that guarantee a resolution up to 60µm for the 1000 mm glasses and 122 µm for the 2000 mm glasses (on long edge leading). It is able to verify the quality of the design up to a circular dot of 0,09 mm2

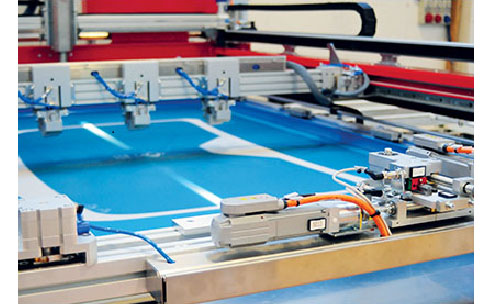

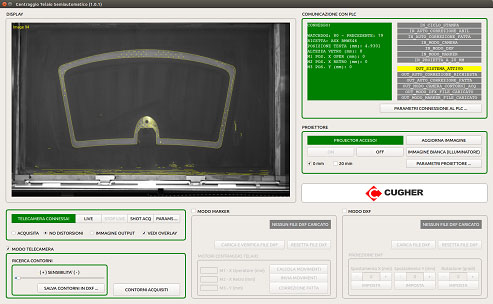

AUTOMATIC SCREEN REGISTRATION SYSTEM WITH CAMERAS

The system is composed of two cameras installed under the printing table and driven by two servo-motors useful to store the data into the recipe. The system is functional to automate the register of the screen with the glass to be printed.

Using of the Automatic screen registration system, allows performing a complete model changeover in an extremely short time: thanks to the completely automatic machine setup, the operator’s actions are reduced only to insert the new screen into the printing machine.

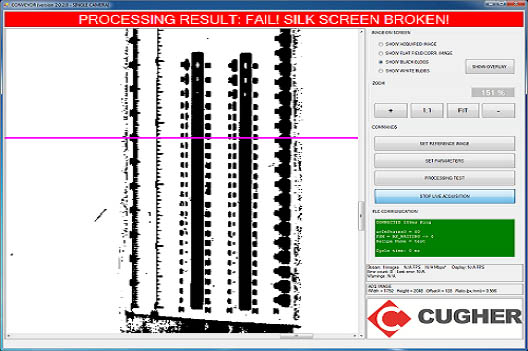

BROKEN SCREEN DETECTION SYSTEM

This special unit has been studied to allow the control of the glass and to check, by means of a dedicated video camera and expertly developed software, the presence of ink spot on the lower surface of the glass. This unit is positioned just down stream from the printing machine, this way it can automatically detect if there is a broken screen.

The minimum detectable spot is a circle with the diameter of 1 mm on a conveyor of 2000 mm width. The advantage of this innovative system is that it doesn’t matter where the screen has been broken or how “small” the hole — if there is a leakage of ink, this unit will detect it.

Contact us today for more custom options: 336-549-6003